The Galvanising process is a process used to protect steel from rust by applying a zinc coating to the steel. The zinc forms a barrier against corrosion in that the steel underneath does not come into contact with water or moisture in the air.

The process consists of 3 distinct phases:

1. Pre-Treatment

2. Galvanizing

3. Inspection

Pre-Treatment

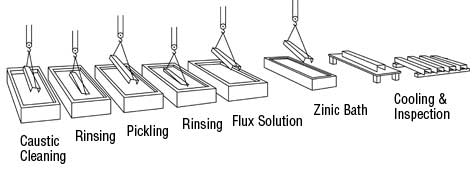

Pre Treatment consists of 4 separate stages:

- Inspection - This involves checking whether the item is adequately vented and that surfaces are checked for signs of contamination with paint, grease, etc. as this would cause the process to fail.

- Degreasing - Steel is immersed in a degreasing solution which removes light oil contamination.

- Pickling - Acid strips the steel surface back to clean base steel.

- Fluxing - A flux solution is applied to the steel to assist with the galvanizing reaction.

Galvanizing

The Item is then immersed in molten zinc at a temperature of around 450 degrees until the temperature of the item is the same as the zinc. During this process the molten zinc reacts with the surface of the steel to form a series of zinc/iron alloys. As the item is removed from the zinc, the zinc on its surface will begin to solidify, as this happens excess zinc is removed to ensure a smooth finish. The item is then usually transferred to a quench tank where it is cooled to allow handling.

Inspection

The galvanized steel is then visually inspected for its appearance and conformity to standards. Batches may then be non-destructively tested for coating thickness and uniformity.