Investing in Excellence

The site covering 12 acres provides space for our 100,000 sq. ft. state of the art production facility with excellent distribution links to all parts of the UK.

-

Drill & Saw Lines

With three drill and saw lines, we are able to process large volumes of steel sections efficiently and economically in readiness for our fabrication teams to work on.

-

Plate Profiling Centres

We have three plate profiling machines with different capabilities to ensure we can cut a vast array of plate sizes and thicknesses.

-

Fabrication Facilities

We have three fabrication workshops where our skilled craftsman fabricate and weld all the products we produce ready for finishing.

-

Powder Coating

We have a dedicated powder coating facility, equipped with the latest environmentally friendly pre-treatment process, offering an extensive range of finishes to steel and aluminium products.

-

Wet Spray

In addition to the powder coating line, we also have a wet spray facility with an integrated extraction system. Giving us the versatility to finish an array of very large products which can’t fit on the powder coating line.

-

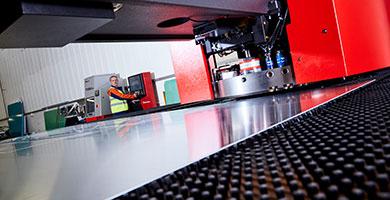

Sheet Metal Production

We have our own sheet metal workshop which houses the latest punch and folding machines enabling us to produce fascias, soffits, flashings and copings to complement our steelwork products.

-

Design Technology

Utilising the latest Tekla software we are able to design and model all of our products working them into full fabrication drawings which integrate with our state of the art machinery.

-

Transport

BoA runs its own transport fleet to ensure our projects are properly serviced. We are FORS Silver accredited and all of our Lorries adhere to the category 6 Ultra-low emissions zones (ULEZ) for London.

-

BOA Academy

With the desire to invest in future generations we opened our own training academy in 2015 consisting of a purpose-built 10,000sq ft fabrication and learning facility. This, in conjunction with our training provider, gave us the opportunity to offer apprenticeships in fabrication, welding and engineering to young people in the local community.

If you wish to make contact with us in respect of the Academy, then please use the Careers page on the website.